Cutting Room - (working process)

Apparel Manufacturing n Marketing

Garment production starts with the

cutting process. In this process, fabric is being cut into components (shapes

or patterns of different garment parts, i.e. front, back, sleeve, collar shapes

etc.). In mass production multiple layers of fabrics are laid on a table and

large number of garments is being cut at a time. The laid fabric stack is

called as lay. The cutting process includes number of sub-processes and flow of

the processes is as following. Each process is briefly explained in the

following:-

|

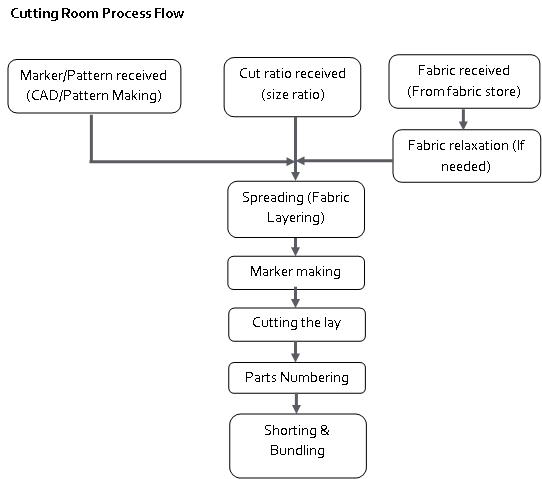

Cutting Room - Process Flow Chart |

1. Pattern / Marker:- According to the design and fit, patterns of different garment parts are made on the pattern paper and cut into pattern pieces. For manual marker these pattern pieces are used for marker making. On the other hand in CAD system patterns are made in computer. Later using a plotter markers are made on sheet. In the second case cutting department receive ready marker.

2. Cut ratio receiving:- Prior to cutting, cutting department get a job sheet from planning department or merchandiser or production manager that includes total quantity of garment pieces to be cut, sizes ratio of the garments and colour-wise size break up. According to the size and colour ratio cutting team prepare one marker or multiple markers. Marker length and number of lay to be cut are planned in this stage.

3. Fabric receiving:- Fabric requirement for an order is calculated according to the average consumption of the fabric from the marker. In case of multiple colour order, colour wise requirement is made. Fabric department issue fabric to cutting against the fabric requirement (generally requisition slip is used).

4. Fabric relaxation:- This process is optional. Specially used for knits fabric. During rolling of fabric it get stretched. So it is essential to bring the fabric on stable form otherwise garment would shrink after making. To relax the fabric roll or than is opened and spread and kept for about 24 hours.

5. Spreading (Fabric Layering):- In this stage fabric sheet is layered one above another maintaining per-defined maker length and correct ply tension. Fabric is layered up to a certain height to avoid cutting quality problem. Spreading is done by manual layering or automatic layering machine can be used. During layering of the fabric, fabric edge is aligned at one side.

6. Marker Making:- After layering of a lay, per made paper patterns (or ready markers made by plotter) are placed on the top layer of the lay. In manual marker making, marking is done around each pattern shape using marking chalk. This process is called as marker making. In a marker all garment components are placed.

7. Cutting:- Lay is cut following the marked lines on the top of the lay. Cutting is done using straight knife or other cutting means. In cutting process garment component are separated. On the basis of pattern shape different cutting method/ machine are selected.

8. Numbering:- Separated garment components are numbered to ensure that in stitching all components from same layer are stitched together. It is important to avoid shade variation in a garment. Between the cutting and sewing processes cut components may be passed through other processes like printing and embroidery. There is maximum chance of mixing of the components. If there is layer number in each component then at the time of stitching only correct components will be stitched together.

9. Sorting:- According to production system (Make through, progressive bundle or one piece flow system) cut components are sorted. In sorting all component of a garment placed together. Size wise sorting and in case multiple colours are cut in a single lay, colour wise sorting will be required.

10. Bundling:- As per the production line requirement a certain number of pieces with all component are tied together. This process is known as bundling. Each bundle is marked with bundle number, style name, size number and quantity of pieces in that bundle. At this stage cutting are ready to send to production line for stitching.

If you have any comment about this post please put your comment on below -

Thanks to Everyone...

onek valo hoysa dada

উত্তরমুছুনLoan Opportunity Offered By Mr, Benjamin That Save My Family From Financial Bondage { 247officedept@gmail.com }

উত্তরমুছুনHello Everyone, I am Putri Adiratnaa single mom from Jakarta, I would like to share this great testimony on how I got a loan from Mr, Benjamin, when we were driven out of our home when I couldn't pay my bills anymore, After being scammed by various companies online and denied a loan from my bank and some other credit union I visited. My children were taken by the foster care, I was all alone in the street. The day i shamefully walked into an old school mate who introduced me to Daisy Maureen. At first I told her that I am not ready to take any risk of requesting a loan online anymore, but she assured me that I will receive my loan from them. On a second thought, due to my homelessness I had to take a trial and applied for the loan, luckily for me I received a loan of $80,000.00 from Mr, Benjamin. I'm happy I took the risk and applied for the loan. My kids have been given back to me and now I own a home and a business of my own. All thanks and gratitude goes to the help of Mr, Benjamin for giving me a meaning to life when i had lost all hope. If you currently seeking for a loan assistance, you can contact them via: {247officedept@gmail.com WhatsApp +1-989-394-3740.